1332-58-7

- Product Name:Kaolin

- Molecular Formula:Al2O3.2SiO2.2H2O

- Purity:99%

- Molecular Weight:258.16

Product Details;

CasNo: 1332-58-7

Molecular Formula: Al2O3.2SiO2.2H2O

Appearance: off-white powder

Chinese Factory Supply High Purity Kaolin 1332-58-7 Cheap Price

Kaolin clay is also called "kaolin", commonly known as "porcelain clay". Composed of kaolinite containing more than 90%. Kaolinite is an important nonmetallic mineral, which is known as one of the four major nonmetallic minerals, together with mica, quartz and calcium carbonate. Kaolinite, a fine grained clay of pure texture, mainly composed of kaolinite or polyhalloysite, was first discovered in gaoling village near jingdezhen, China. Is mainly composed of less than 2 microns tiny sheet, fold, tubular flake minerals such as kaolinite cluster (kaolinite, dickite and nacrite, halloysite, etc.), the chemical formula which best characterizes the ideal for AL2O3-2 sio2-2 h2o, its main mineral compositions are kaolinite and much water kaolinite, in addition to the kaolinite mineral clusters, and the montmorillonite, illite and pyrophyllite, quartz and feldspar and other minerals associated. The chemical composition of kaolin contains a large amount of AL2O3, SiO2, a small amount of Fe2O3 and TiO2, as well as K2O, Na2O, CaO and MgO in the micro kaolinite structure diagram.

Kaolin occurs as a white to grayish-white colored, unctuous powder free from gritty particles. It has a characteristic earthy or claylike taste, and when moistened with water it becomes darker in color and develops a claylike odor.

|

Type |

Size(mesh) |

|

Washed Kaolin |

200 |

|

325 |

|

|

600 |

|

|

1250 |

|

|

Calcined Kaolin |

325 |

|

800 |

|

|

1250 |

|

|

4000

|

|

|

6000 |

|

|

Meta-kaolin |

325 |

|

item |

value |

|

Dimensions |

325-8000mesh |

|

SiO2 Content (%) |

50.81% |

|

Fe2O3 Content (%) |

0.89% |

|

Al2O3 Content (%) |

46.62% |

|

Moisture Content (%) |

0.08% |

|

TiO2 Content (%) |

0.6% |

|

K2O Content (%) |

0.2% |

|

Application |

Ceramic/porcelain |

|

Shape |

White Power |

|

Packing |

25/50 Kgs |

|

MOQ |

15 tons |

|

Product name |

Kaolin Clay |

|

Advantages |

High Whiteness |

|

Size |

325mesh- 8000mesh |

Clacined kaolin is derived from the washed kaolin after high temperature sintering at 1700oC, while

meta-kaolin is obtained from washed kaolin as well after sintering at relatively low temperature between 600oC to 800oC. Kaolin has become a necessary mineral raw material for dozens of industries such as paper making, ceramics, rubber, chemicals, coatings,

national defense; etc.

Product features:

-Stickiness and thixotropy

-Sinterability

-Fire resistance

- Suspension

- Adsorption

-Chemically stable

- Electrical insulation

Application:

-For preparing synthetic turbid water that is employed to evaluate the biosorption capacity of Moringa oleifera leaves.

-In combination with carrageenan to induce arthritic inflammation in a rat model for evaluating the activity of JAK3 (janus kinase 3) inhibitors.

-In a study to assess its utility for microparticle-enhanced cultivation (MPEC).

-kaolin (China clay) is a mixture of various aluminum silicates. It is often used in powders and masks given its absorbent, abrasive, bulking, and opacifying properties. This white, soft powder has good coverage and absorption abilities for both water and oil, making it an appropriate absorber of the oil and sweat secreted by the skin. It adheres well to the skin’s surface, yet is easily removed with normal cleansing procedures. Kaolin is considered a non-comedogenic raw material.

-Adsorbant.

| Packaging | 1kg-15kg packing | 2 PE bag inside + 1 foil bag outside in carton | ||

| 25kg-50kg packing | 2 PE bag inside + 1 foil bag outside in drum | |||

| Other packing | Customized packing | |||

| Drum Size | D38cm*H60cm or customized, 25 kg/ drum | |||

| Shipping | 1-50kg | International Express | Fast and convenient | Door to Door |

| 50-500kg | Air Transportation | Fast and cheap | To Air Port | |

| Above 500kg | Sea Transportation | Cheap and convenient | To Port | |

Kaolin(Cas 1332-58-7) Usage

|

Overview |

Kaolin, with its unique properties and versatile applications, plays a crucial role in various industries, including ceramics, paper manufacturing, medicine, cosmetics, and industrial processes. Its natural origin, chemical inertness, and wide availability make it an indispensable material in modern manufacturing and technology. |

|

Uses |

Ceramics: Kaolin is extensively used in the ceramics industry for manufacturing porcelain, pottery, and ceramics due to its plasticity, white color, and ability to enhance firing properties. |

|

storage |

Kaolin is a stable material. Since it is a naturally occurring material, kaolin is commonly contaminated with microorganisms such as Bacillus anthracis, Clostridium tetani, and Clostridium welchii. However, kaolin may be sterilized by heating at a temperature greater than 160°C for not less than 1 hour. When moistened with water, kaolin darkens and becomes plastic. Kaolin should be stored in a well-closed container in a cool, dry place. |

|

Incompatibilities |

The adsorbent properties of kaolin may influence the absorption of other orally administered drugs. Drugs reportedly affected by kaolin include amoxicillin; ampicillin;cimetidine; digoxin; lincomycin; phenytoin; and tetracycline. Warfarin absorption by rat intestine in vitro was reported not to be affected by kaolin. With clindamycin, the rate (but not the amount) of absorption was affected by kaolin. |

|

Regulatory Status |

Accepted in Europe as a food additive in certain applications. Included in the FDA Inactive Ingredients Database (oral capsules, powders, syrups, and tablets; topical preparations). Included in nonparenteral medicines licensed in the UK. |

|

Who Evaluation |

Evaluation year: 2015 |

|

EXPOSURE ROUTES |

inhalation, skin and/or eye contact |

|

FIRST AID |

(See procedures) Eye:Irrigate immediately Breathing:Fresh air |

1332-58-7 Relevant articles

Kaolin: processing, properties and applications

M.S. Prasad a, K.J. Reid a, H.H. Murray b

, Applied Clay Science Volume 6, Issue 2, September 1991, Pages 87-119

his review outlines the geology and occurrence of kaolins in the world and the state of the art in processing high-quality kaolins. The physical and chemical characteristics of kaolin are also reviewed with respect to their use for specific applications in paper, ceramics and refractories, plastics, rubber, adhesives and paint industries.

Kaolin in paper filling and coating

Wayne M. Bundy a, Joseph N. Ishley b

, Applied Clay Science Volume 5, Issues 5–6, March 1991, Pages 397-420

Increase in the aspect ratio of kaolin, as opposed to increase in surface area, exerts the dominant influence on the increase in low-shear viscosity. Although low-shear viscosities of undelaminated coating grades of kaolin show good correlation with surface area, the relationship breaks down for delaminated grades.

1332-58-7 Process route

-

- 1332-58-7

kaolin

-

sodium lignosulphonate

-

sodium lignosulphonate

| Conditions | Yield |

|---|---|

|

|

-

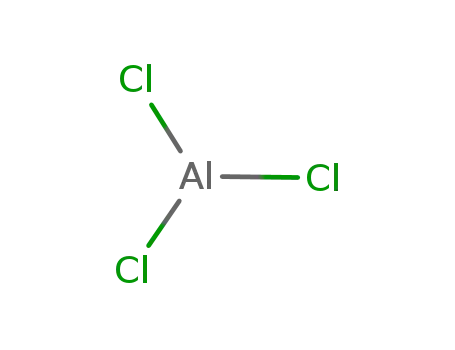

- 7446-70-0

aluminium trichloride

-

phillipsite (K,Na,Ca)(Si,Al)8O16*6H2O#(K,Na,Ca)2(Si,Al)8O16*6H2O

-

phillipsite (K,Na,Ca)(Si,Al)8O16*6H2O#(K,Na,Ca)2(Si,Al)8O16*6H2O

-

- 1332-58-7

kaolin

-

-

pyrophyllite

| Conditions | Yield |

|---|---|

|

In water; High Pressure; phillipsite and an aq. soln. of AlCl3 is encapsulated in a gold bomb, heating to 300°C at a pressure of 30 MPa for 4 weeks, quenching to room temp.; XRD;

|

1332-58-7 Upstream products

-

7446-70-0

aluminium trichloride

1332-58-7 Downstream products

-

112760-32-4

Al0.2N1.8O1.2Si1.8, low temperature

-

112926-00-8

silica gel